Chemical Process Design Module

Chemical Process Design Module

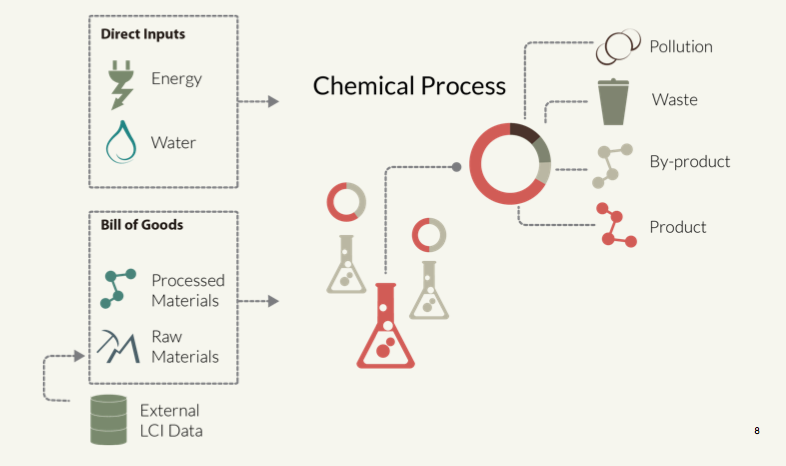

The goal of the Chemical Process Design Module is, with as little information as possible, to calculate key parameters that can be used to evaluate the performance of a given chemical transformation. These parameters include the rate of generation of products, byproducts, and wastes; minimum energy requirements; raw material requirements; efficiency of raw material usage; and an upper limit on efficiency of raw materials usage (e.g. how much waste is being produced compared to what is the least amount of waste that can be produced). To date this algorithm has been used to investigate several chemistries of industrial significance including the alkylation of butane to form iso-octane and the production of phthalic anhydride from o-xylene.

Predictive Life Cycle Impact Inventory Module

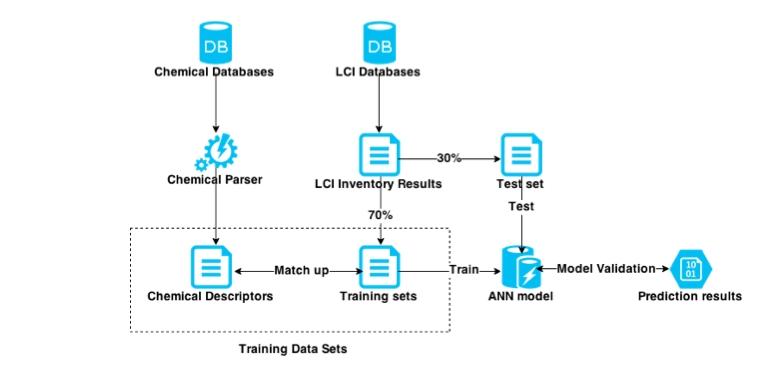

The predictive life cycle inventory (LCI) module can provide CLiCC users an estimate of chemical LCI (e.g. energy & water requirements) for the synthesis process, when users are unable to provide data necessary for the chemical process design module. This alternate approach may result in more uncertainty, but may be necessary when information on the chemical’s synthesis is not completely available. The predicted LCI values will be based on chemical structural features using Artificial Neural Networks (ANNs) to relate chemical structure to LCI values.